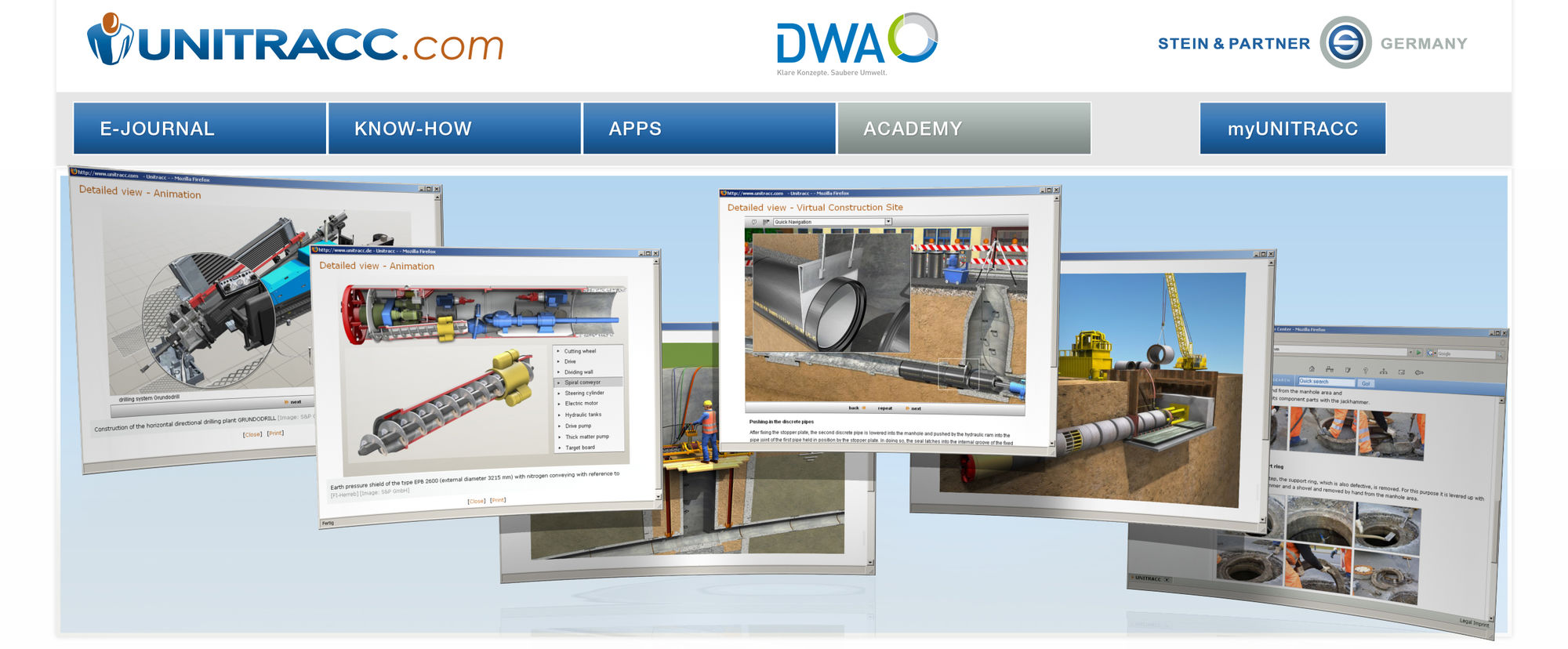

E-Learning

Learn more about our e-learning modules

Infobox

Course overview

BE-01 Wastewater collection systems and their significance in water management

To inspect, repair, renovate, replace and expand the existing drainage systems and respectively to adjust the sustainable development to the more stringent demands on the public health and safety as well as the environmental protection, is the great task of all in planning, construction, operation, maintenance, renovation and management involved persons of these systems. This requires expert knowledge. This module provides the essential basic knowledge of drain and sewer systems to understand the structure and mode of operation, to recognize their importance for water management and to classify the own actions as part of an „integrated sewer system management“.

Learning content: Water cycle, history of municipal drain and sewer systems, fundamentals of sewer drainage systems, sewers, manholes and sewer structures, wastewater collection systems.

BE-02 Installation of water pipes, drains and sewers using the open cut method

The installation of water pipes, in particular, drains and sewers is worldwide in large part performed using the open cut method. This at first glance „simple“ construction method is actually highly complex when implemented in urban areas and at large depths. The numerous boundary conditions, shoring-, and installation systems require extensive technical knowledge in order to ensure a high quality of workmanship.

Learning content: Geotechnical and hydrogeological principles, utility trench construction, embedment of piping, occupational health and safety around excavations.

BE-05 Maintenance of drain and sewer systems – Cleaning I

Cleaning is one of the most important maintenance measures when it comes to ensuring a continuous performance of drainage systems. This module covers essential knowledge regarding the cause and effect of deposits, and provides a strategic approach to the development of a cleaning plan that enables for the optimisation of operating costs and in particular asset preservation.

Learning content: Solids in sewers, cleaning strategy and program, high pressure cleaning/cleaning vehicles, cleaning nozzles.

BE-06 Maintenance of drain and sewer systems – Cleaning II

Cleaning is one of the most important maintenance measures when it comes to ensuring a continuous performance of drainage systems. This module expands on the topics covered in module „D-05 cleaning I“, by providing further knowledge on the applications and limits of flushing methods, mechanical cleaning methods and special methods, such as physical and chemical sewer cleaning. Discussed are both the accessible and non-accessible lines, as well as pressure lines. It concludes with providing constructive solutions for the minimization of solids entry into the sewer system, with the aim of preventing the formation of deposits and hence the reduction of cleaning efforts and frequencies.

Learning content: Flushing methods, mechanical and miscellaneous methods, cleaning of large profiles, cleaning of pressure lines, constructive design measures for the reduction of deposit.

BE-15 Replacement of sewers and drains

Replacement refers to the installation of new sewers and drains in place of existing pipelines, where the new pipeline takes over the functions of the old sewer or drain. The replacement process is subdivided into three methods: „open cut method“, „semi open cut method“ and „trenchless method“. The focus of this module is the trenchless replacement method of pipelines by the means of pipe bursting, gallery techniques, and pipe extraction. In addition to the replacement method and process description this module discusses the areas of application and limits, the advantages and disadvantages as well as possible rehabilitation errors and options for quality assurance.

Learning content: Pipe bursting basics, pipe bursting, the welding of plastic pipes, pullback of pipelines, gallery techniques, pipe extraction, geotechnical and hydrogeological principles.

BE-21 Utility Tunnelling

The installation of supply and disposal lines is still mostly performed using the open cut method consisting of digging a trench, laying the pipe under the protection of shoring, and subsequently backfilling the trench. Given the many disadvantages associated with this method along with the growing environmental awareness of the population, it is imperative that trenchless technologies be taken more strongly into account in the planning and construction of pipelines and utility networks.

Learning content: Geotechnical fundamental, pipe jacking, microtunnelling, jacking pipes, jacking steering, starting and target shafts.